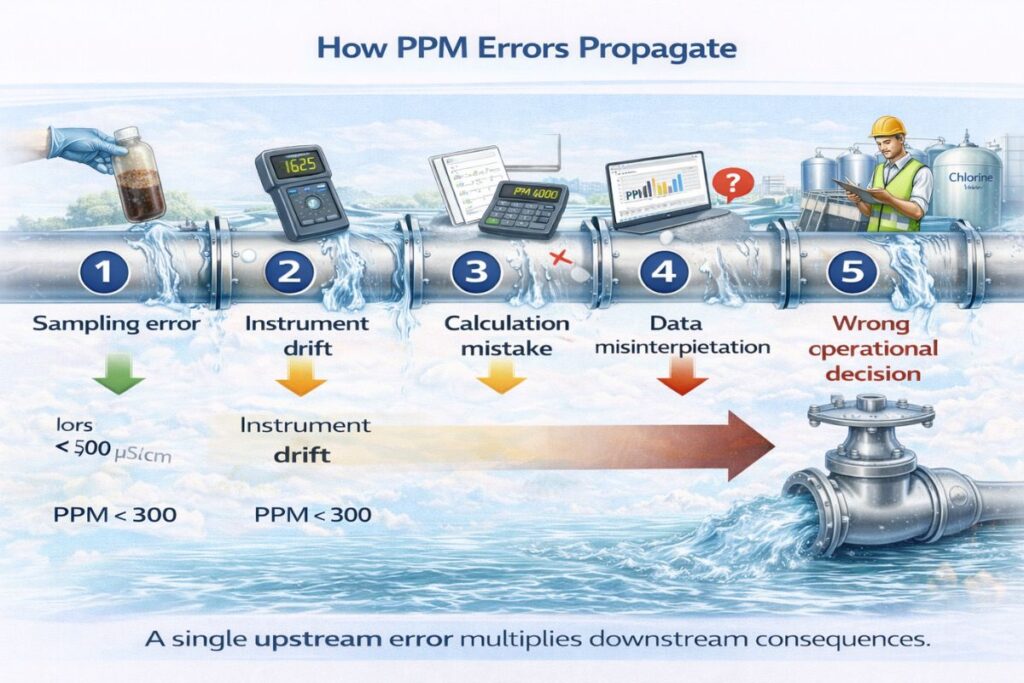

Accurate chemical concentration measurement is the backbone of water treatment, agriculture, pharmaceuticals, manufacturing, and environmental monitoring. Yet, even experienced professionals make ppm measurement mistakes that compromise data reliability and decision-making.

A small error in ppm calculation can lead to:

- Incorrect chemical dosing

- Regulatory non-compliance

- Product quality failures

- Health and safety risks

- Financial losses

From misreading instruments to using the wrong ppm formula, these mistakes affect beginners and professionals alike.

This practical troubleshooting guide identifies the top 10 ppm measurement mistakes, explains their root causes, and provides clear solutions—helping you achieve consistent, defensible, and high-precision results.

What Is PPM and Why Accuracy Matters

Understanding Parts Per Million

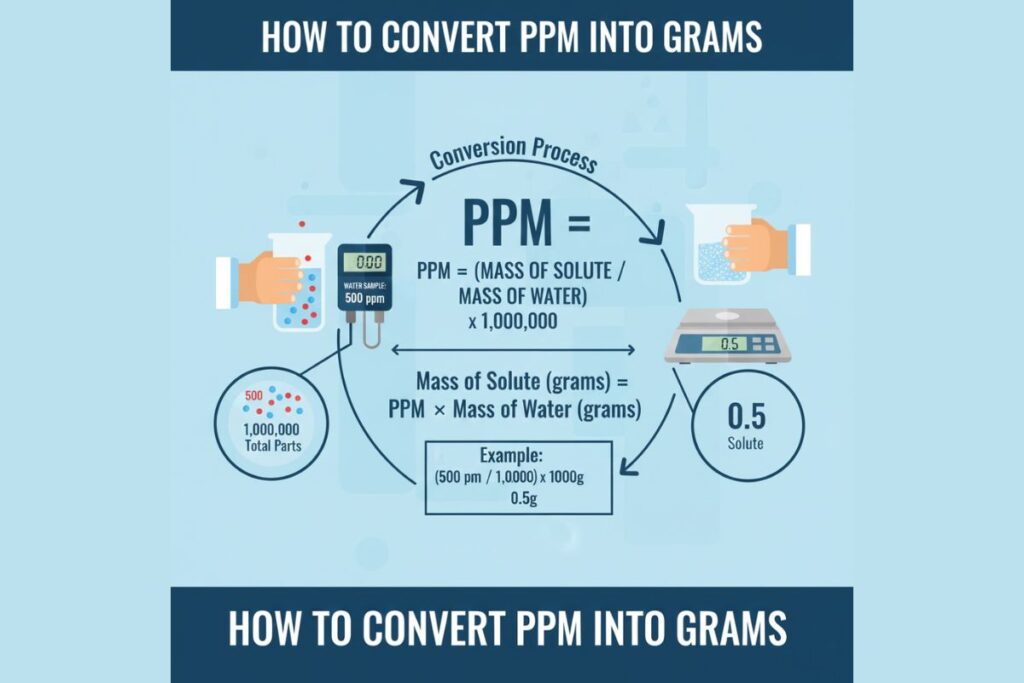

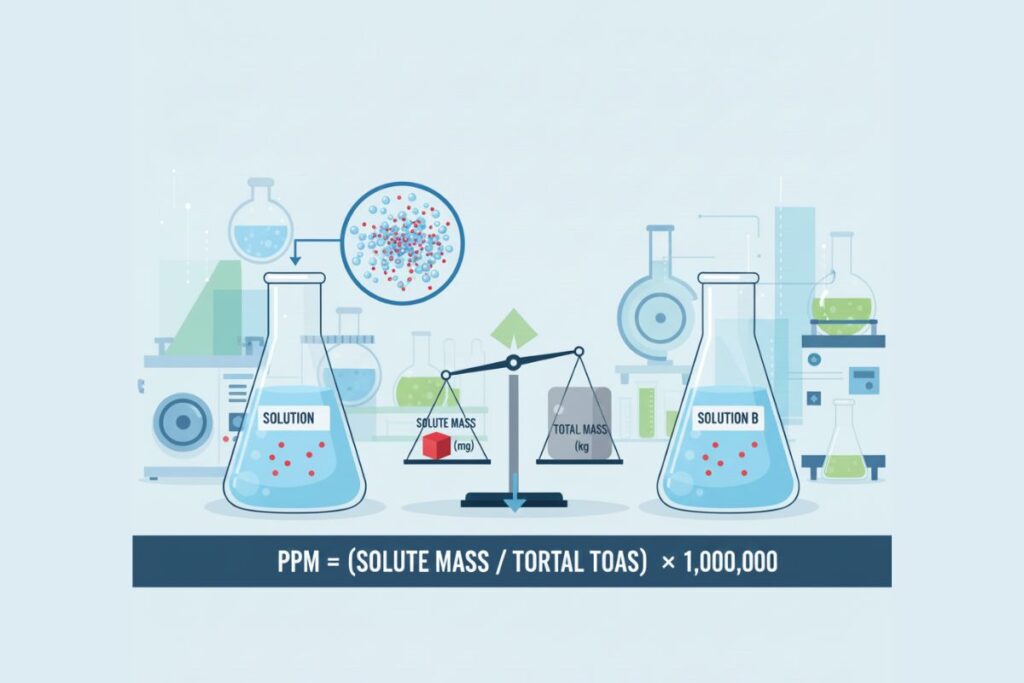

Parts per million (ppm) expresses the amount of a substance per one million parts of a solution or material.

In water systems:

1 ppm ≈ 1 mg/L

This equivalence simplifies regulatory reporting and laboratory analysis.

Importance of Precise PPM Measurement

Accurate ppm values support:

✔ Safe drinking water

✔ Correct fertilizer dosing

✔ Reliable pharmaceuticals

✔ Efficient industrial processes

✔ Environmental protection

Errors distort concentration measurement and undermine system control.

This is why eliminating ppm measurement mistakes is critical.

Top 10 PPM Measurement Mistakes — And How to Fix Them

1. Using Uncalibrated Instruments

The Problem

Meters and sensors drift over time, producing inaccurate readings.

Example

A TDS meter shows 350 ppm instead of actual 420 ppm.

Fix

✔ Calibrate weekly

✔ Use certified standards

✔ Maintain calibration logs

Case Study

A water utility reduced reporting errors by 42% after adopting monthly calibration schedules.

2. Confusing PPM with mg/L and mg/kg

The Problem

Users assume ppm is always equivalent to mg/L or mg/kg.

Reality

- Water: 1 ppm ≈ 1 mg/L

- Soil: 1 ppm ≈ 1 mg/kg

- Other liquids: Density matters

Fix

Use density corrections for non-water systems.

Calculation Example

Liquid density = 1.2 kg/L

Reading = 10 mg/L

PPM = 10 / 1.2 = 8.3 ppm

3. Ignoring Sample Contamination

The Problem

Dirty containers introduce foreign material.

Industry Example

Trace metals from steel containers inflated readings by 15%.

Fix

✔ Use acid-washed bottles

✔ Avoid metal tools

✔ Wear gloves

4. Incorrect Dilution Factor Application

The Problem

Forgetting to account for dilution during analysis.

Example

Original sample diluted 1:10

Measured = 5 ppm

Actual = 50 ppm

Fix

Always record dilution factors.

Formula

Actual PPM = Measured × Dilution Factor

5. Misapplying the PPM Formula

The Problem

Using incorrect mathematical relationships.

Standard PPM Formula

PPM = (Mass of Solute / Mass of Solution) × 1,000,000

Frequent Error

Dividing by volume instead of mass in solids.

Fix

Verify formula suitability for each matrix.

6. Overlooking Temperature Effects

The Problem

Temperature changes affect EC-based ppm readings.

Example

At 35°C, EC increases by ~7%.

Fix

✔ Use temperature-compensated meters

✔ Apply correction factors

7. Relying on Fixed EC-to-PPM Conversion Factors

The Problem

Using a universal factor (0.5 or 0.7) regardless of water type.

Reality

Different ions conduct differently.

Comparison Table

| Water Type | Conversion Factor |

|---|---|

| Drinking | 0.5 |

| Irrigation | 0.65 |

| Industrial | 0.7 |

Fix

Select factor based on water chemistry.

8. Inadequate Sampling Methods

The Problem

Non-representative samples distort results.

Visual Explanation

Sampling from surface only vs mixed-depth sampling.

Fix

✔ Composite sampling

✔ Multiple locations

✔ Consistent depth

9. Premature Rounding of Data

The Problem

Rounding too early reduces accuracy.

Example

Raw = 3.456 ppm

Rounded early → 3.5 ppm

Final error → ±1.3%

Fix

Round only in final reporting.

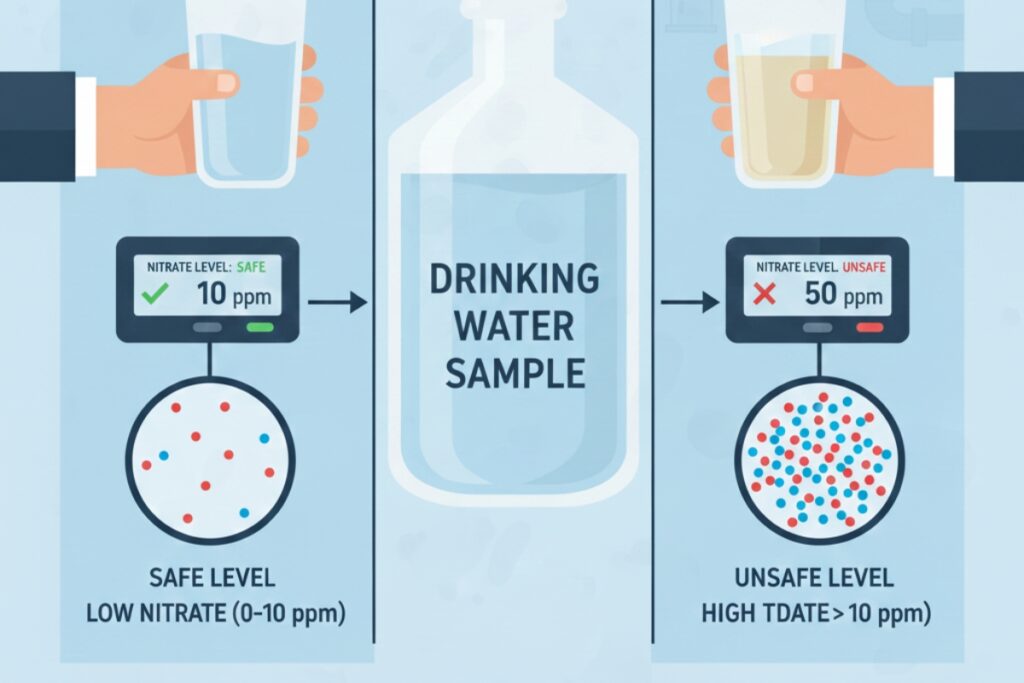

10. Misinterpreting Regulatory Limits

The Problem

Confusing ppb and ppm standards.

Example

Arsenic limit = 10 ppb (0.01 ppm)

Reported = 0.1 ppm → 10× unsafe

Fix

Always confirm unit basis.

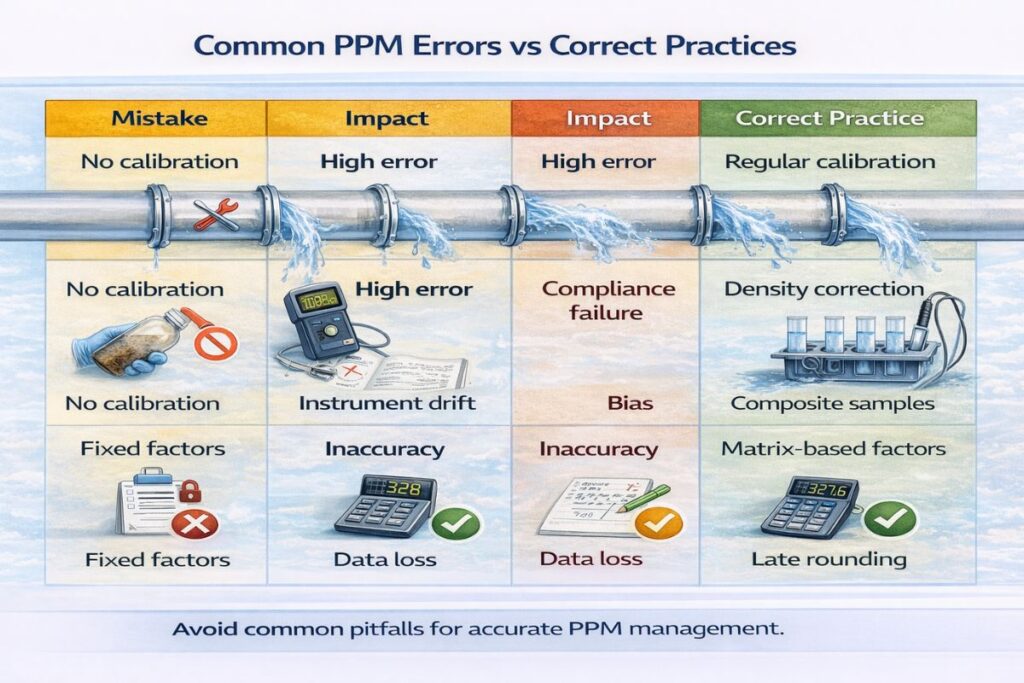

Common PPM Errors vs Correct Practices

Comparison Table

| Mistake | Impact | Correct Practice |

|---|---|---|

| No calibration | High error | Regular calibration |

| Wrong units | Compliance failure | Density correction |

| Poor sampling | Bias | Composite samples |

| Fixed factors | Inaccuracy | Matrix-based factors |

| Early rounding | Data loss | Late rounding |

Calculation Walkthrough: Correcting a Faulty PPM Measurement

Scenario

Measured EC = 1,000 µS/cm

Used factor = 0.5

Temperature = 32°C

Actual factor = 0.65

Step 1: Temperature Correction (≈5%)

Corrected EC = 1,000 × 0.95 = 950

Step 2: Apply Proper Factor

PPM = 950 × 0.65 = 618 ppm

Original Report

500 ppm (incorrect)

Correct Value

618 ppm (accurate)

Error = 23.6%

Industry Case Study: Pharmaceutical Batch Rejection

Background

A pharma company reported solvent residue = 8 ppm.

Limit = 10 ppm

Audit found:

- Dilution factor ignored

- Actual = 16 ppm

Impact

- Batch rejected

- ₹2.5 crore loss

Resolution

Standardized ppm calculation procedures and digital tools.

Tools & Calculators for Error-Free PPM Measurement

Manual calculation increases risk. Digital tools reduce human error.

Trusted Platform: ppmcalculation.com

ppmcalculation.com provides professional-grade tools for accurate measurement:

Advantages

- Validated ppm formulas

- Automatic corrections

- Mobile-friendly interface

- No registration

- Audit-ready outputs

These tools significantly reduce ppm measurement mistakes.

Common Mistakes Recap Checklist

Before finalizing any ppm report, verify:

✔ Instrument calibrated

✔ Units validated

✔ Sample uncontaminated

✔ Dilution applied

✔ Temperature corrected

✔ Proper factor used

✔ Rounding delayed

Use this checklist for quality control.

Frequently Asked Questions (FAQs)

1. What is the most common ppm measurement mistake?

Skipping calibration is the most frequent and damaging error.

2. Can ppm errors affect regulatory compliance?

Yes. Even minor deviations can lead to violations.

3. Are cheap meters reliable?

Only for screening. Professional work requires certified instruments.

4. Why do lab and field results differ?

Due to temperature, contamination, and calibration differences.

5. How often should ppm instruments be calibrated?

Weekly for critical systems, monthly for routine monitoring.

6. Is ppm always better than ppb?

No. Toxic contaminants often require ppb-level analysis.

Eliminating PPM Measurement Mistakes for Reliable Results

Avoiding ppm measurement mistakes is essential for scientific integrity, safety, and compliance.

Key Takeaways

✔ Calibration is non-negotiable

✔ Use correct ppm formula

✔ Account for density and temperature

✔ Apply dilution factors

✔ Interpret limits carefully

✔ Use validated digital tools

Systematic error control ensures trustworthy concentration measurement.

Related PPM Calculators

Explore more water quality and chemistry tools: