Clean drinking water is one of the most essential public health requirements in modern society. From municipal supply systems to industrial water treatment plants, every liter of water must meet strict quality and safety standards before reaching consumers.

At the center of this process lies PPM calculation in water treatment and purification. Engineers, operators, and regulators rely on parts per million (ppm) measurements to determine chemical dosing, monitor contaminants, and ensure compliance with legal limits.

A small error in ppm calculation can result in:

- Under-dosing, leading to microbial contamination

- Over-dosing, causing chemical toxicity

- Regulatory violations and penalties

- Loss of public trust

Whether you are a water treatment professional, environmental engineer, student, or concerned consumer, understanding how ppm works is essential for safe water management.

This guide explains the science, formulas, applications, real-world examples, and best practices of ppm measurement in water purification systems.

What Is PPM in Water Treatment?

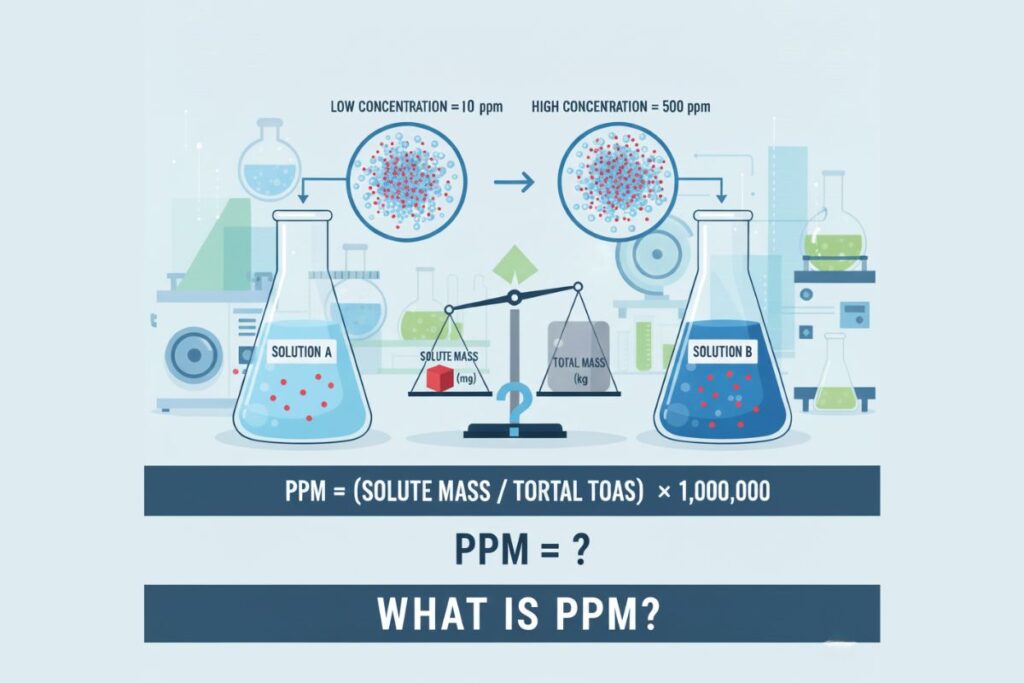

Understanding Parts Per Million

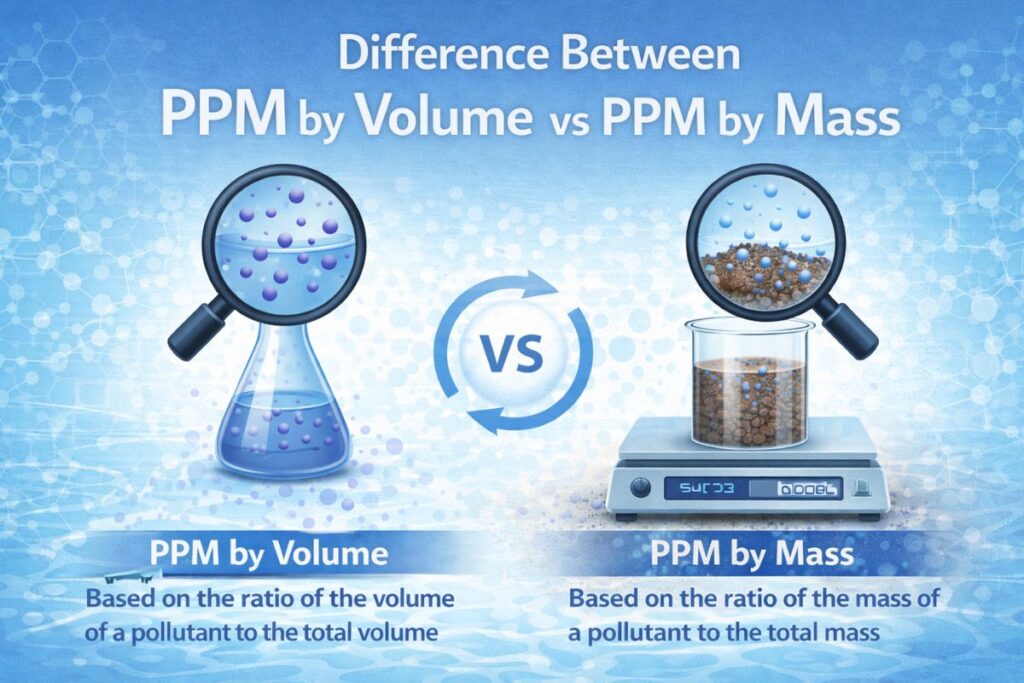

Parts per million (ppm) expresses the concentration of a substance relative to one million parts of water.

In water systems:

1 ppm ≈ 1 mg/L

This equivalence exists because 1 liter of water weighs approximately 1 kilogram.

Why PPM Is the Standard Unit

PPM is widely used in water treatment because it is:

✔ Easy to calculate

✔ Compatible with lab instruments

✔ Recognized by regulators

✔ Suitable for low-level contaminants

It enables precise concentration measurement for both chemicals and pollutants.

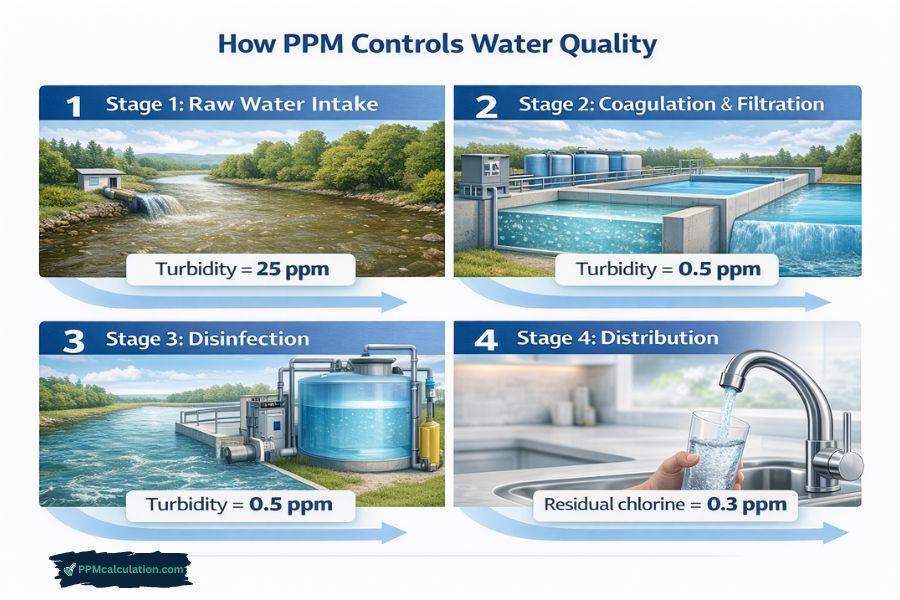

Role of PPM Calculation in Water Treatment and Purification

PPM measurements guide almost every stage of water treatment.

1. Chemical Dosing Control

Treatment plants use chemicals to:

- Disinfect water

- Remove turbidity

- Adjust pH

- Control corrosion

Each chemical is dosed based on ppm values.

2. Contaminant Monitoring

Water is continuously tested for:

- Heavy metals

- Microorganisms

- Nitrates

- Fluoride

- Organic compounds

All limits are defined in ppm or lower units.

3. Regulatory Compliance

Government agencies define maximum allowable concentrations in ppm or ppb.

Example:

| Parameter | Limit |

|---|---|

| Chlorine | 4 ppm |

| Fluoride | 1.5 ppm |

| Nitrate | 10 ppm |

| Lead | 0.015 ppm |

4. Public Health Protection

Accurate ppm control prevents:

- Waterborne diseases

- Chemical poisoning

- Long-term toxicity

Key Water Treatment Parameters Measured in PPM

| Parameter | Purpose | Typical Range |

|---|---|---|

| Chlorine | Disinfection | 0.2–4 ppm |

| Turbidity | Clarity | <1 ppm |

| TDS | Dissolved solids | <500 ppm |

| Fluoride | Dental health | 0.7–1.2 ppm |

| Iron | Aesthetic quality | <0.3 ppm |

| Nitrate | Health safety | <10 ppm |

These values are monitored daily in treatment plants.

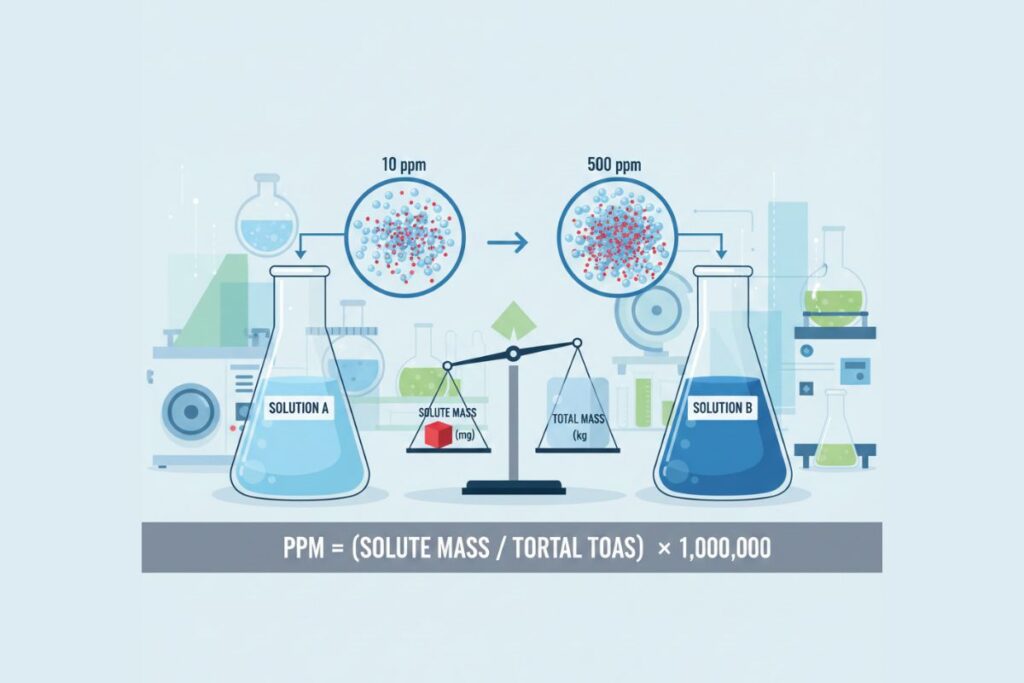

PPM Formula for Water Treatment Applications

Standard PPM Formula

The basic ppm formula is:

PPM = (Mass of Solute / Mass of Solution) × 1,000,000

For water systems:

PPM ≈ mg/L

Practical Engineering Formula

For dosing calculations:

Required Chemical (mg) = Desired ppm × Volume (L)

This simplified formula is widely used in plant operations.

Calculation Walkthrough: Chlorine Dosing Example

Scenario

A treatment plant needs to dose chlorine at 2 ppm in a 50,000 L storage tank.

Step 1: Apply Formula

Required Chlorine (mg) = 2 ppm × 50,000 L

= 100,000 mg

Step 2: Convert to Grams

100,000 mg = 100 g

Result

The plant must add 100 grams of chlorine.

This is a classic ppm example used in daily operations.

PPM to mg/L Conversion in Water Treatment

Why It Matters

Most laboratory reports provide results in mg/L. Operators often need ppm.

Conversion Rule

For water:

1 ppm = 1 mg/L

Example

Laboratory report:

Arsenic = 0.05 mg/L

= 0.05 ppm

This is above the safe limit (0.01 ppm), requiring immediate action.

This stepwise reduction demonstrates how ppm guides purification.

Industry Case Study 1: Municipal Water Chlorination Failure

Background

A mid-sized city experienced bacterial contamination.

Test Results:

- Chlorine residual: 0.05 ppm

- Required minimum: 0.2 ppm

Analysis

Under-dosing reduced disinfection efficiency.

Impact

- 3,000 people affected

- Temporary boil-water advisory

- ₹1.2 crore remediation cost

Solution

Improved real-time ppm monitoring and automated dosing.

Industry Case Study 2: Fluoride Overdosing Incident

Scenario

A rural treatment plant overdosed fluoride.

Measured:

- Fluoride = 3.8 ppm

- Standard limit = 1.5 ppm

Root Cause

Manual ppm calculation error.

Consequences

- Dental fluorosis risk

- Public complaints

- Legal action

Prevention

Adoption of digital ppm converters and training.

Comparison: Manual vs Automated PPM Control

| Feature | Manual System | Automated System |

|---|---|---|

| Accuracy | Medium | High |

| Response Time | Slow | Real-time |

| Human Error | High | Low |

| Cost | Low | Medium |

| Compliance | Risky | Reliable |

Modern plants increasingly prefer automated systems.

PPM in Different Water Treatment Processes

1. Coagulation and Flocculation

Alum dosing: 10–50 ppm

Controls suspended solids removal.

2. Softening

Lime dosing: 100–300 ppm

Reduces hardness.

3. Reverse Osmosis

Feed TDS: <2,000 ppm

Permeate: <50 ppm

4. Disinfection

Chlorine/Ozone: 0.5–3 ppm

Ensures pathogen control.

Tools & Calculators for PPM Calculation

Manual calculation is useful, but digital tools increase efficiency.

Trusted Platform: ppmcalculation.com

ppmcalculation.com provides professional-grade tools for water engineers and operators, including:

Benefits

- High accuracy

- Instant results

- Mobile compatibility

- No registration required

- Engineering-tested formulas

These tools support daily plant operations and compliance reporting.

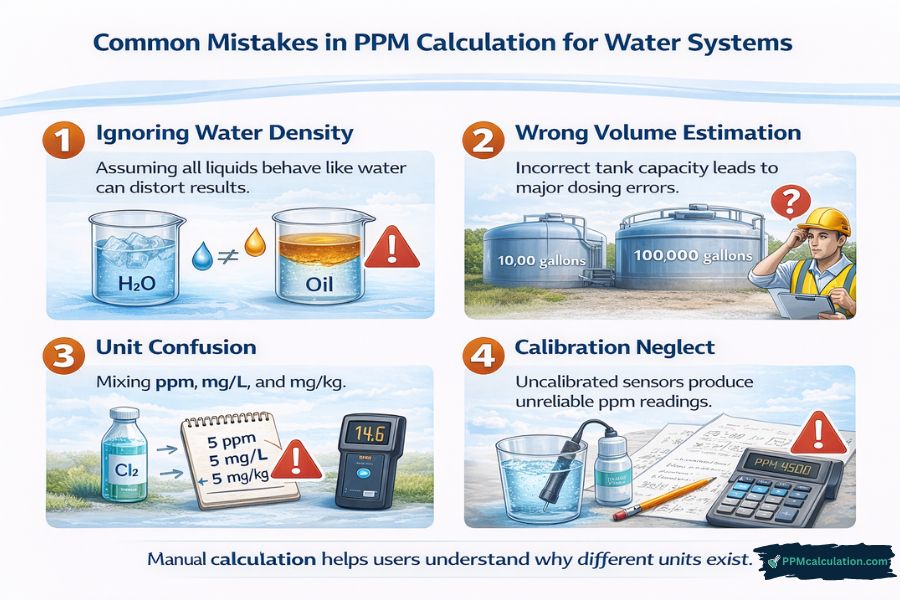

Common Mistakes in PPM Calculation for Water Systems

1. Ignoring Water Density

Assuming all liquids behave like water can distort results.

2. Wrong Volume Estimation

Incorrect tank capacity leads to major dosing errors.

3. Unit Confusion

Mixing ppm, mg/L, and mg/kg.

4. Calibration Neglect

Uncalibrated sensors produce unreliable ppm readings.

5. Over-Reliance on Manual Methods

Manual calculation increases operational risk.

Frequently Asked Questions (FAQs)

1. Why is ppm used instead of percentage in water treatment?

Because contaminants are usually present in very small amounts, making percentages impractical.

2. Is ppm the same as mg/L for all waters?

Only for water with density near 1 kg/L. High salinity requires correction.

3. How often should ppm be monitored?

Critical parameters like chlorine should be monitored continuously or hourly.

4. What is the safe chlorine level in drinking water?

Typically between 0.2 and 4 ppm.

5. Can consumers measure ppm at home?

Yes. Test kits and digital meters can measure basic parameters like TDS and chlorine.

6. Which contaminants require ppb monitoring?

Lead, arsenic, mercury, and pesticides are often regulated in ppb.

Why PPM Calculation Drives Safe Water Systems

PPM calculation in water treatment and purification is the foundation of modern drinking water safety.

Key Takeaways

✔ PPM controls chemical dosing

✔ Ensures regulatory compliance

✔ Protects public health

✔ Optimizes treatment efficiency

✔ Prevents costly failures

From coagulation to disinfection, every treatment stage depends on accurate parts per million measurement.

Related PPM Calculators

Explore more water quality and chemistry tools: