When a Few PPM Can Mean the Difference Between Safety and Catastrophe

Industrial facilities operate with chemicals that, even at low concentrations, can pose serious risks to ecosystems and human health. In environmental protection, early detection at the parts per million (ppm) level often determines whether a minor leak becomes a full-scale disaster.

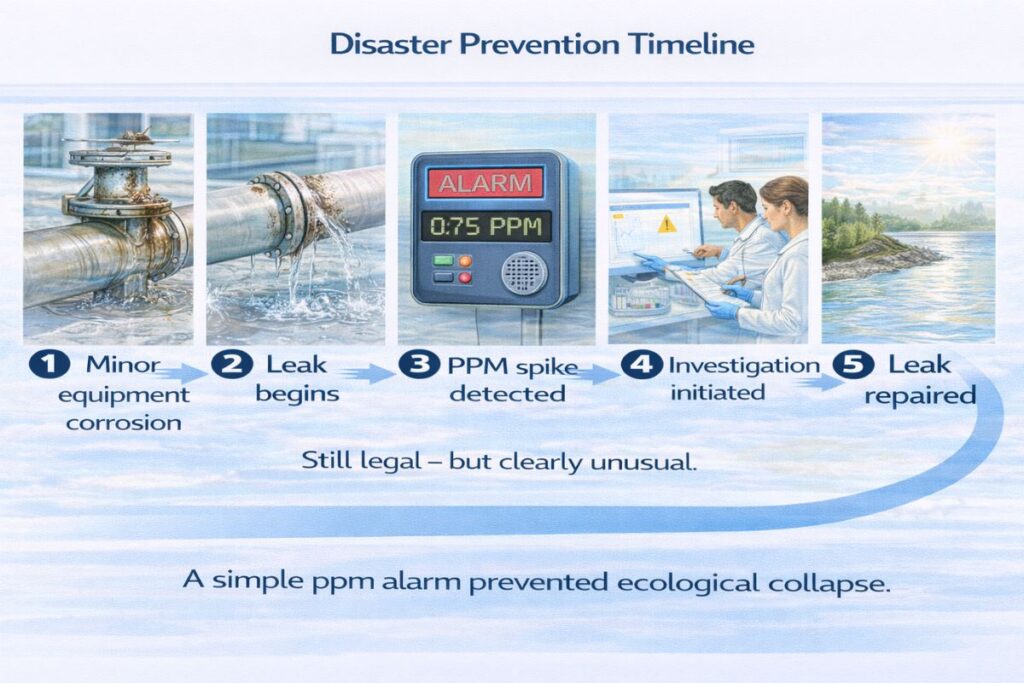

This case study explores how ppm monitoring prevented an environmental disaster when trace chemical detection in a river system triggered rapid intervention. The incident demonstrates the importance of precise ppm calculation, real-time concentration measurement, and regulatory compliance in modern environmental management.

Even a difference of 0.5 ppm can decide whether:

- Fish populations survive

- Drinking water remains safe

- A company faces multi-million-dollar penalties

- A local community is evacuated

Understanding how ppm monitoring works—and why it matters—can help industries, regulators, and environmental professionals prevent future crises.

Background: The Industrial River Corridor

The Setting

A mid-sized chemical manufacturing plant was located upstream of a river supplying drinking water to approximately 1.2 million people. The plant handled organic solvents and metal-based catalysts.

Regulatory Framework

The facility operated under strict discharge permits requiring:

- Continuous monitoring

- Monthly compliance reporting

- Maximum contaminant levels expressed in ppm

The regulated pollutant in focus: Phenolic compounds, with a discharge limit of 0.5 ppm.

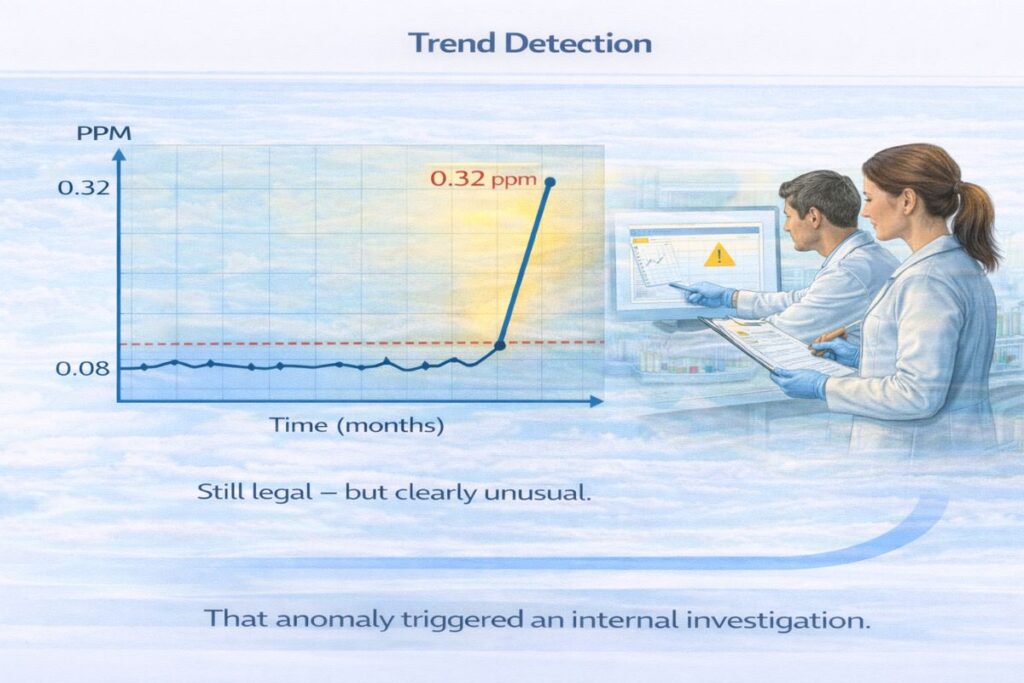

The Early Warning Signal: A Slight PPM Increase

During routine automated monitoring, sensors recorded:

- Baseline average: 0.08 ppm

- Sudden reading: 0.32 ppm

Though still below the 0.5 ppm legal threshold, the increase was statistically abnormal.

Understanding the Science Behind PPM Monitoring

What Is PPM in Water Monitoring?

In water systems:

1 ppm ≈ 1 mg/L

This equivalence simplifies environmental reporting.

Standard PPM Formula Used

PPM = (Mass of Pollutant / Volume of Water) × 1,000,000

Environmental labs typically measure in mg/L, which directly equals ppm in freshwater.

Investigation Phase: Confirming the Data

Step 1: Verification Sampling

Multiple samples collected:

- Upstream

- At discharge point

- Downstream

Step 2: Laboratory Analysis

Using Gas Chromatography (GC-MS), confirmed:

Phenol concentration = 0.31 ppm

Step 3: Dilution Check

No dilution errors detected.

Calculation Walkthrough: Estimating Spill Volume

Engineers estimated discharge flow rate:

River flow rate = 2,000,000 L/hour

Measured concentration = 0.31 ppm

Step 1: Convert PPM to mg/L

0.31 ppm = 0.31 mg/L

Step 2: Calculate Mass per Hour

Mass/hour = 0.31 mg/L × 2,000,000 L

= 620,000 mg/hour

= 620 grams/hour

If sustained for 24 hours:

620 g × 24 = 14.88 kg

Nearly 15 kilograms of phenol could enter the river in a single day.

This demonstrated the urgency—even below legal limits.

Root Cause Analysis

Investigation revealed:

- A corroded transfer valve

- Minor leakage into wastewater stream

- Undetected during visual inspection

Without ppm monitoring, the leak could have continued for weeks.

Preventive Action Taken

Immediate Measures

✔ Shut down affected line

✔ Isolated discharge stream

✔ Activated secondary containment

Long-Term Fixes

✔ Valve replacement

✔ Corrosion-resistant materials

✔ Increased sensor frequency

Within 48 hours, readings returned to 0.07 ppm.

What Could Have Happened Without PPM Monitoring?

Projected Scenario

If undetected for 30 days:

620 g/hour × 24 × 30 = 446.4 kg

Nearly half a metric ton of phenol could have contaminated the river.

Potential Consequences

- Fish mortality

- Drinking water contamination

- Legal penalties exceeding ₹100 crore

- Community health crisis

PPM monitoring prevented escalation.

Industry Comparison: Early Detection vs Late Detection

| Factor | Early Detection | Late Detection |

|---|---|---|

| Concentration | <0.5 ppm | >5 ppm |

| Ecological Damage | Minimal | Severe |

| Cleanup Cost | Low | Extremely high |

| Legal Impact | None | Major fines |

| Public Trust | Maintained | Lost |

Environmental Chemistry Perspective: Why 0.3 ppm Matters

Even sub-ppm levels affect aquatic life.

Toxicological Threshold

Fish acute toxicity level: ~1 ppm

Chronic exposure at 0.2–0.5 ppm can cause:

- Reproductive harm

- Growth inhibition

- Oxygen depletion

This case illustrates how ppm in environmental chemistry supports proactive risk management.

Comparison: PPM vs PPB in Environmental Emergencies

| Unit | Sensitivity | Use Case |

|---|---|---|

| PPM | Moderate | Nutrients, solvents |

| PPB | High | Heavy metals |

| PPT | Ultra-high | Persistent toxins |

For this case, ppm was sufficient for early detection.

Case Study Parallel: Mercury Monitoring in Wetlands

A similar incident occurred in a mining region:

Mercury baseline = 0.001 ppm

Detected spike = 0.004 ppm

Early intervention prevented bioaccumulation.

This reinforces the value of continuous monitoring.

Tools & Calculators for PPM Monitoring

Manual calculation increases risk during emergencies. Digital tools enhance response speed.

Trusted Platform: ppmcalculation.com

ppmcalculation.com supports environmental professionals with:

Advantages

- Accurate ppm formula implementation

- Instant results

- Mobile-friendly interface

- No registration required

- Supports rapid field decisions

In crisis scenarios, accurate ppm calculation saves time—and ecosystems.

Common Mistakes in Environmental PPM Monitoring

1. Ignoring Small Deviations

Minor increases can signal major problems.

2. Overlooking Trend Analysis

Focus on patterns, not just thresholds.

3. Delayed Calibration

Sensor drift can hide leaks.

4. Poor Documentation

Incomplete records hinder response.

5. Failure to Apply Dilution Factors

Underreporting contaminant levels.

FAQs: How PPM Monitoring Prevents Environmental Disasters

1. Why detect pollution below legal limits?

Because trends matter more than single values.

2. How sensitive are ppm sensors?

Modern instruments detect down to 0.001 ppm.

3. Can ppm monitoring prevent oil spills?

Yes, especially in wastewater and discharge streams.

4. Is ppm monitoring expensive?

Costs are minor compared to disaster cleanup.

5. How often should monitoring occur?

Continuous monitoring is ideal for high-risk facilities.

6. What industries benefit most?

Chemical manufacturing, mining, oil & gas, pharmaceuticals, wastewater plants.

Key Lessons: How PPM Monitoring Prevented an Environmental Disaster

This case clearly shows:

✔ Early ppm detection prevented escalation

✔ Accurate ppm calculation quantified risk

✔ Real-time monitoring enabled rapid response

✔ Proactive action saved millions

✔ Environmental damage was avoided

The difference between 0.08 ppm and 0.32 ppm changed the outcome.

Summary: The Power of Precision in Environmental Protection

Understanding how ppm monitoring prevented an environmental disaster highlights the importance of accurate trace-level analysis.

In environmental chemistry:

- Small ppm changes reveal hidden risks

- Trend analysis predicts failures

- Rapid calculation supports decision-making

- Digital tools enhance accuracy

- Continuous monitoring protects ecosystems

Environmental safety depends not on reacting to disasters—but on detecting them before they occur.

Related PPM Calculators

Explore more water quality and chemistry tools: