Calibration solutions play a critical role in laboratories, manufacturing plants, and scientific research where accurate measurement is essential. A commonly used standard is the 1000 PPM solution, especially in chemical analysis, water testing, environmental monitoring, and material purity verification. Understanding what a 1000 PPM solution means and how it is prepared ensures precise calibration, reliable instruments, and traceable analytical results.

What Does PPM Mean in Calibration Standards

PPM stands for Parts Per Million. It expresses concentration by comparing one part of a substance to one million parts of the whole solution. In calibration standards, PPM is used to define how much analyte or chemical is present in a solution that will later be used to adjust instruments. A 1000 PPM standard means that in one million parts of the total volume, 1000 parts belong to the target chemical.

In simple terms, 1000 PPM is the same as 1000 milligrams of solute in one liter of solution, which equals 1 gram per liter. This standard concentration provides a stable and reliable reference for calibrating devices such as spectrometers, chromatographs, and sensors.

Why 1000 PPM Standards Are Commonly Used

The 1000 PPM concentration is widely used because it offers a versatile starting point for dilution. From this concentration, analysts can prepare a wide range of lower PPM solutions easily and accurately. It ensures the stock solution remains stable, highly measurable, and traceable to certified reference materials.

This concentration is a practical middle ground. It is not too concentrated to cause safety issues during handling, and not too weak to introduce errors while diluting. It also simplifies calculations for preparing calibration curves in analytical testing.

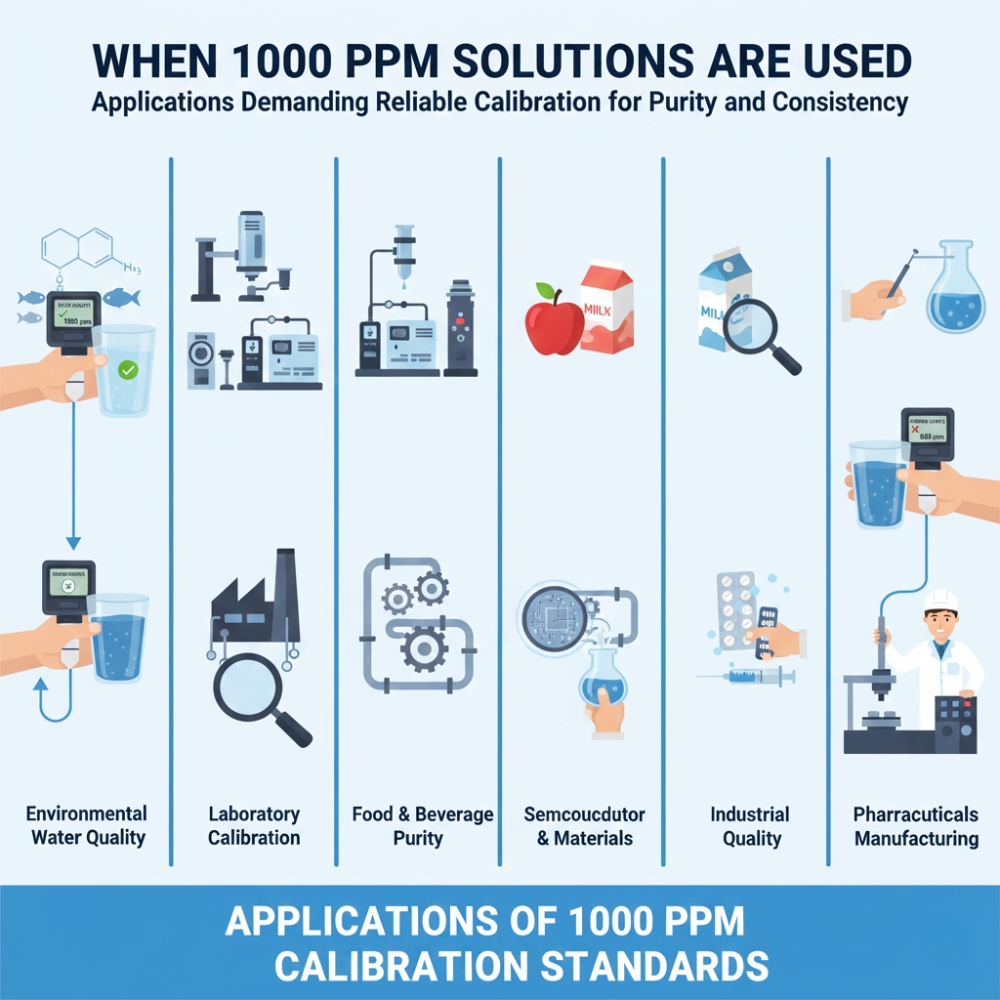

When 1000 PPM Solutions Are Used

A 1000 PPM calibration standard is used whenever a specific chemical or element must be detected at low concentrations. Some common uses include:

- Environmental water quality testing to detect fluoride, nitrates, metals, chlorine, and other dissolved contaminants

- Calibration of laboratory equipment like ICP-MS, AAS, HPLC, and titration systems

- Food and beverage purity testing for trace elements and preservatives

- Semiconductor and advanced materials contamination monitoring

- Industrial chemical quality control for consistency and safety

- Pharmaceutical manufacturing to ensure regulated purity and dosage accuracy

- Each application demands reliable calibration to avoid inaccurate measurements that may lead to product failures or compliance issues.

How to Prepare a 1000 PPM Solution

To make a 1000 PPM calibration solution, the amount of solute must be carefully measured, and the final volume must be accurate. The general formula for PPM is:

PPM = (Mass of solute in mg / Volume of solution in L)

For a 1000 PPM solution:

Mass of solute needed = 1000 mg, which equals 1 gram

Final volume = 1 liter

The preparation steps depend on whether the solute is a solid or a liquid.

Preparing a 1000 PPM Solution Using a Solid Solute

When using a pure solid chemical:

- Weigh exactly 1 gram of the solute using an analytical balance

- Transfer the solid carefully into a volumetric flask

- Add distilled or deionized water until reaching the 1-liter mark

- Mix thoroughly until fully dissolved

Solids must be highly pure to ensure accurate calibration. Any impurity would alter actual concentration and cause measurement deviations.

Preparing a 1000 PPM Solution Using a Liquid Solute

When the solute is a liquid with known density:

- Calculate the volume needed to equal 1000 mg of solute

- Use a calibrated pipette to transfer the measured liquid

- Dilute with distilled water up to 1 liter in a volumetric flask

- Mix gently to ensure uniform consistency

Liquids with varying density require more careful calculation to avoid errors.

Importance of Accurate Volume and Purity

Two major factors influence the quality of a calibration solution:

- Purity of the solute

- Accuracy of the final volume

Volumetric glassware, such as Class A flasks and pipettes, is required to ensure precise volume measurement. Water must be free from dissolved minerals or contaminants that could interfere with test results. Temperature also affects the solution volume, therefore labs maintain room temperature control during preparation.

How 1000 PPM Standards Improve Laboratory Accuracy

Analytical instruments require calibration based on known concentration solutions. A 1000 PPM standard acts as a reference point that allows:

- Instrument response checks and corrections

- Creation of multi-level calibration curves using dilutions

- Improved detection of trace chemicals

- Consistency across multiple test runs

- Confidence that reported data meets compliance and certification requirements

Poor calibration can result in inaccurate readings that lead to incorrect decisions, product failures, or regulatory violations.

Diluting a 1000 PPM Standard to Lower Concentrations

Dilution is the most common operation performed using a 1000 PPM stock. The dilution formula is:

C1 × V1 = C2 × V2

Where C1 and V1 are the concentration and volume of stock solution, and C2 and V2 are the final concentration and volume of the diluted solution.

Example:

To prepare 100 PPM from 1000 PPM:

Take 10 ml of 1000 PPM solution and dilute to 100 ml

This ability to create precise concentration levels from a single stock solution makes 1000 PPM standards versatile in many testing environments.

Certified Calibration Standards vs Laboratory-Prepared Solutions

Certified standards are supplied by accredited manufacturers and come with a certificate of analysis. They include:

- Guaranteed concentration accuracy

- Traceability to international reference materials

- Shelf-life and stability information

- Contamination-free packaging

In contrast, lab-prepared solutions may introduce errors due to weighing or dilution mistakes. For critical compliance testing, certified reference standards are recommended.

Storage and Handling Requirements

Proper storage ensures consistency throughout usage. Key recommendations include:

- Store in clean, sealed containers to prevent contamination

- Avoid exposure to sunlight which may degrade certain substances

- Label solutions clearly with concentration, date, and chemical name

- Use proper safety equipment depending on chemical hazard classification

- Replace solutions regularly based on stability data to maintain accuracy

Calibration failures often result from expired or improperly stored solutions.

Industries That Depend on 1000 PPM Calibration Standards

A wide range of industries rely on high-accuracy PPM standards every day:

- Water treatment plants testing for harmful contaminants

- Semiconductor fabs requiring ultra-pure materials

- Food quality labs checking for additives and trace metals

- Medical device and pharma industries verifying chemical purity

- Automotive and aerospace engineering detecting microscopic residues

In all these fields, even tiny measurement differences can impact safety and performance.

Conclusion

A 1000 PPM calibration solution is a widely used standard in chemical analysis because it offers precision, consistency, and a convenient base for creating accurate dilutions. It ensures that instruments deliver reliable results essential for regulatory compliance, quality control, and scientific integrity. Understanding how to prepare, store, and use these standards is vital for laboratories and industries that depend on exact concentration measurements to maintain safety and product excellence.